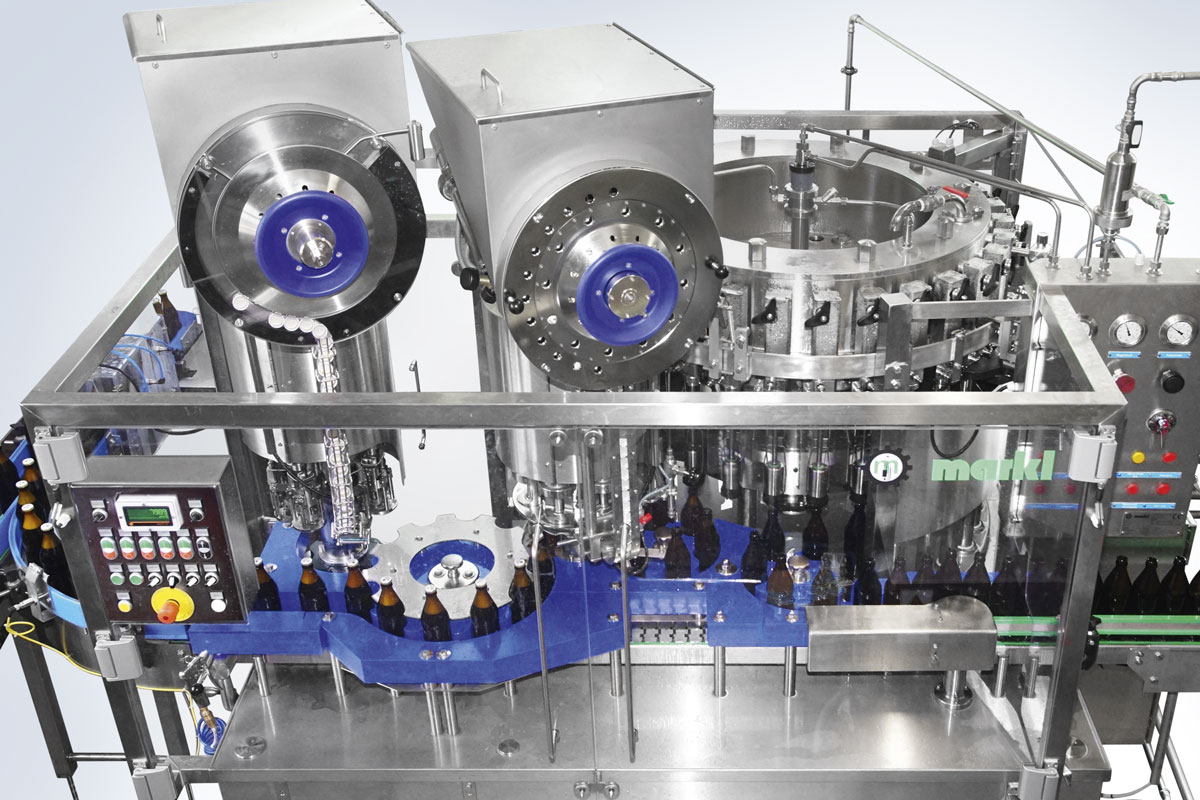

Long-tube filling machines with and without capper

Filling systems operating according to the long-tube filling principle ensure a particularly low oxygen absorption by the filling medium – the best prerequisite for long shelf life of the bottled beverage. They are therefore ideal for aroma-friendly filling of beer.

Markl long-tube bottle filling machines with pre-evacuation also have a elaborated pressurized gas management. This makes it possible to avoid double pre-evacuation – and reduces CO2 consumption to only around 60% of the demand with double pre-evacuation.

The compact Markl filling machines in monoblock design are also available combined with a single or double capper. This results in a flexible bottle filling and capping system, for example for crown corks and screw caps.

To seam beverage cans, we integrate systems from proven suppliers into your Markl system – either from Ferrum (CH) or Lubeca (D).

Markl offers complete machine solutions, for craft brewers as well as for small and medium-sized breweries and beverage manufacturers. Depending on your requirements, we will supplement your Markl long tube filling and capping machine with additional modules – from upstream depalletizing, transporting and rinsing to final packaging of bottles, cans and boxes. Markl also offers combined systems – for filling bottles and cans in a common plant.

Long tube filling machine, here with double capper (crown cork and screw cap)

Robust and easily accessible: The filling and capping area of the Markl Bavaria