Filling and capping systems

for bottles and cans

Filling and capping systems

for bottles and cans

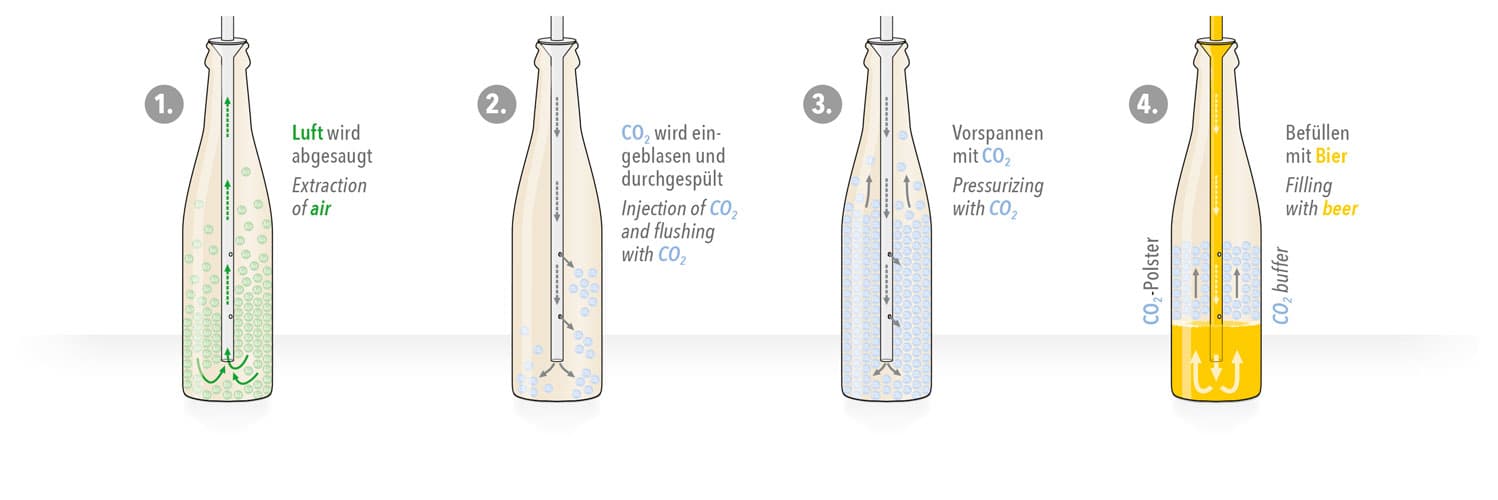

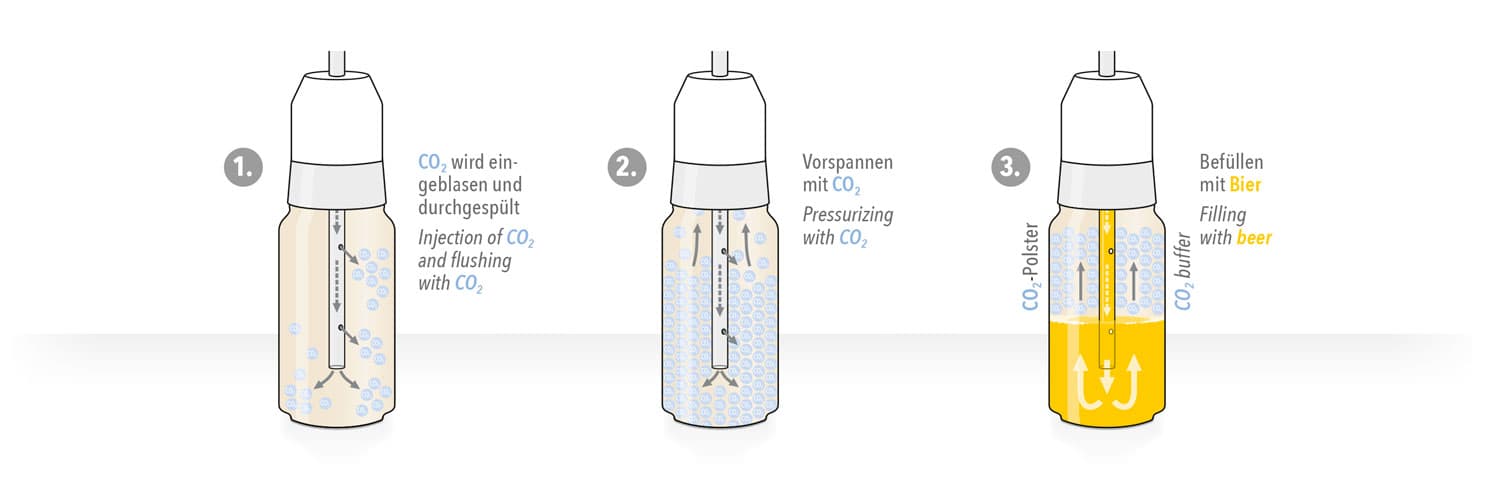

Low-oxygen filling and capping concept

for premium beverage filling

Markl is a strong partner for the beverage industry for more than 30 years. We offer efficiently working, reliable machines for filling and sealing of glass bottles, cans and PET bottles, supplemented by appropriate transport systems for bottles and crates.

Our practical designs take into account the experience gained from many years of mechanical engineering and are subject to continuous development.

Benefits of Markl filling machines

- Very low oxygen intake (0.01 mg/l) while filling – due to an elaborate pressurized gas management, combined with single pre-evacuation

- Only 60 % CO2 consumption compared to double pre-evacuation

- High efficient CIP cleaning

- Filling valves in hygienic design, highly polished inside for easy cleaning

- Reinforced and sealed drive sections

- Overall construction set-up for decades of durability

- Complete solutions from depalletizing to packaging possible

Beverages

- Beer

- Lemonade

- Soft drinks

- Water

- Juice

- Wine

- Other mixed drinks

Typical output

1,000 to 15,000 units/hour

Markl long-tube counterpressure filling method